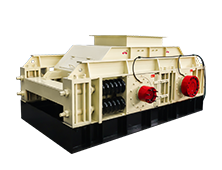

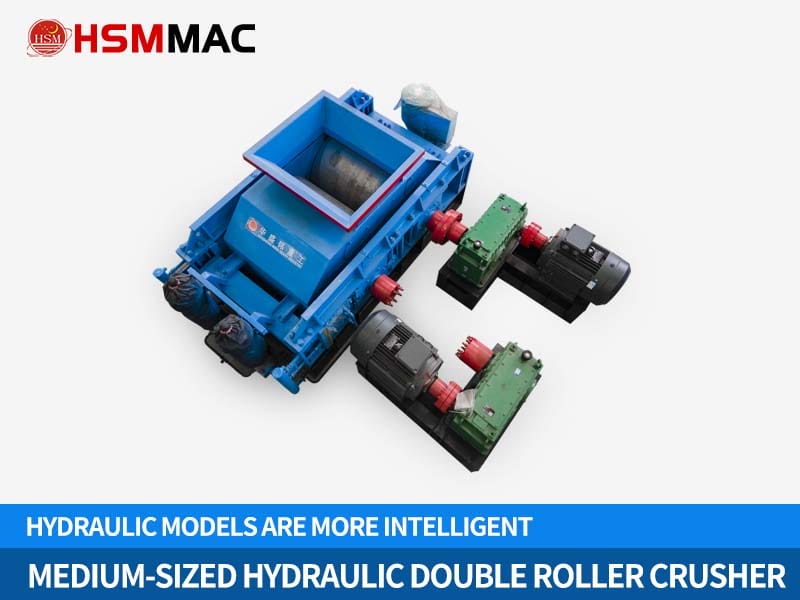

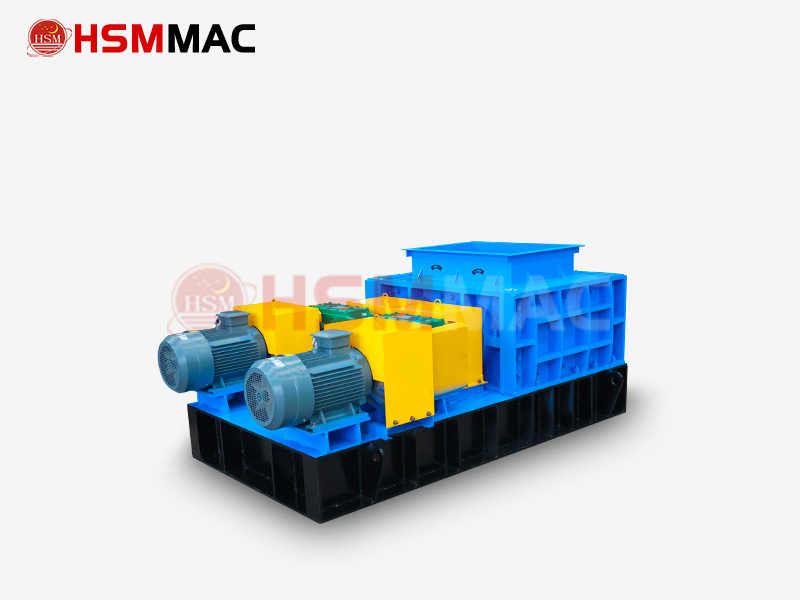

Small Mobile Crusher: Hydraulic Double Roller Crusher

2025-12-12

Looking for a compact, high-efficiency crushing solution tailored for small-scale projects? Whether it’s small quarry operations, construction waste recycling, or rural infrastructure improvement, the small mobile hydraulic double roller crusher stands out as your top choice! Featuring a flexible mobile design, this crusher can be easily moved between construction sites, quarries, or recycling yards without complicated fixed installation—saving you time and labor on site transfer. Its advanced hydraulic drive system not only ensures ultra-stable operation with low noise but also allows precise adjustment of the crushing gap, enabling it to handle various materials (limestone, coal, construction waste, shale, gypsum, etc.) into different particle sizes as needed. It also boasts outstanding practical advantages: small overall size that saves storage and transportation space, low energy consumption that cuts operating costs effectively, and simple maintenance due to its streamlined structure (key components are easy to disassemble and replace). These traits make it ideal for small and medium-sized enterprises, individual contractors, or on-site emergency crushing tasks. Whether it’s road base construction, rural house renovation, or small-batch ore processing, this crusher delivers consistent and reliable performance. Want to get detailed technical parameters, customized configuration plans, or the latest quotation of this crusher? Leave a message...